Product Description

Electrical contractors routinely create scrap metal products such as wire and cable,

aluminum conduit, cable tray, copper pipe, and even switchgear on the jobsite,

but they may not realize the value of these materials can significantly boost their bottom line.

The keys to getting the highest price for these items are knowing exactly how to collect and sort the material and bringing it to the proper scrap processing facility.

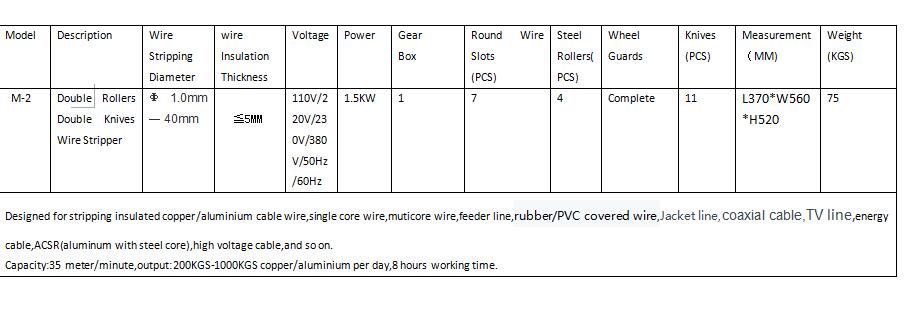

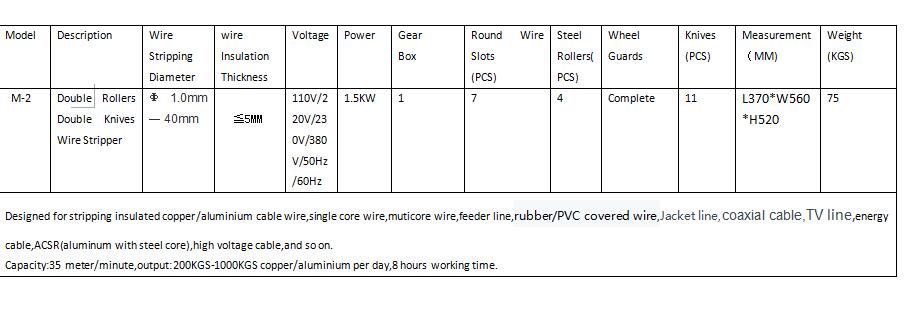

Scrap Electric Copper Cable Wire Separator

M-2 Bench 9 slots Type

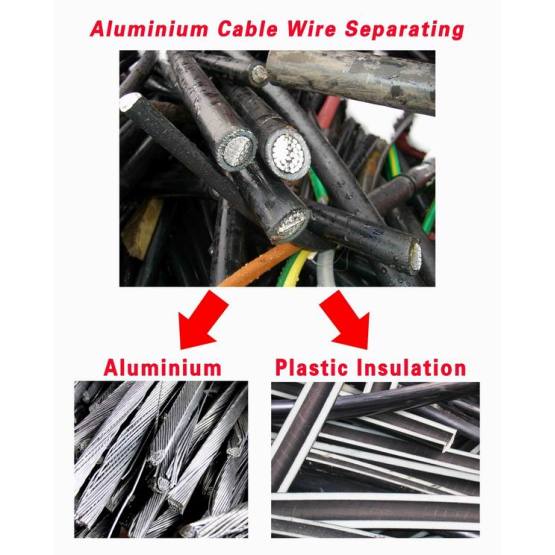

An environmentally safe way to remove wire insulation,Designed for Electricians, Demolition Companies, Supply Houses, and Recyclers.

This wire stripper is a bench mounted machine that grips the wire from one side and cuts and removes the insulation from the other simultaneously.Recycle the copper and aluminum wires.

Power supply 2.2KW,230V-50HZ

Processing diameter at 1-40mm cable wire

Wire stripping capacity 35 meter/minute

Output 50kgs/hour,depends on wire diameter

Measurement 370*560*550mm

Weight 80kgs

Steel rolls 4sets.

Blades 15 pieces

Slots 9 pieces

This machine add with 2 more slots for flat cable wire.

*Once the machine is set for one size of wire,you can strip that size continuously,without adjusting your machine.

*Hardened Steel Slitter Blades.

*Heavy Duty Gearbox Drive.

*Industrial on-off switch with separate Emergency Stop Button.

Machine Use Instructions:

1.Inspect whether the moving parts of the machine are adequately oiled (this includes grease on moving gears and oil on sprockets and chains); inspect knife points for marring or damage; inspect the machines screws and bolts to check whether they are loose, tighten if necessary.

2.After inspection is complete and all repairs are finished; switch on the power source; decide which channel to cut the cable in (proper channel depends on size of wire, settings of lower mandrel screw, tension of upper spring screws, ect.; choice of which channel depends on these factors); put the cable into the channel for testing (cable/wire length should not exceed 1 meter); turn off the switch after peeling; test if the desired results have been met.

.png) Contact Now

Contact Now